Sandblasting VS. Waterblasting – Which is best for your building?

Sandblasting and waterblasting are two popular methods for surface preparation and cleaning. Sandblasting uses abrasive materials, such as sand, to remove surface contaminants and smooth out surfaces. Waterblasting, on the other hand, uses high-pressure water to blast away contaminants and dirt.

Both methods can be used for surface preparation. Making sure that your surface is clean will go a long way when applying paint or other treatments. Sandblasting and waterblasting can both remove paint, grime buildup, oil, rust, and other contaminants that may be on your building. Both are great ways to preserve your building.

They both involve high-pressure equipment that uses a nozzle to direct either sand or water at a surface, effectively removing unwanted substances. Despite using different abrasive materials, both methods can be effective in preparing surfaces for painting or other treatments. Additionally, both sandblasting and waterblasting should only be performed by trained professionals to ensure safety and proper application.

Waterblasting Benefits

Less Dust – In some areas, sandblasting is restricted because of the dust plumes and high populations. This technique cuts downs on the harmful dust that can happen when sandblasting.

More Versatile – Waterblasting has more versatile applications, while sandblasting is often used for specific applications.

Great Prep for Coating – Waterblasting leaves a lightly etched surface that is great prep if you’re planning to apply a coating to the area.

Sandblasting Benefits

More Effective – Sandblasting can be more effective than waterblasting for removing thick coatings or heavily rusted surfaces.

Faster – The water in waterblasting acts as a lubricant. Because sandblasting doesn’t have this, the work can get done faster, specifically if it is removing heavy coatings or sealants.

Great for Industrial – Sandblasting is often used in large-scale industrial projects, such as cleaning concrete or buildings.

Sandblasting Restrictions

Sandblasting can be more dangerous than waterblasting because dust clouds can form and be harmful if inhaled. Because of this, in highly populated areas, it can be a better option to waterblast. Some cities and states also require permits for sandblasting.

In conclusion, both waterblasting and sandblasting have their advantages and disadvantages when it comes to surface preparation and cleaning. While waterblasting may be a more environmentally friendly option, sandblasting may be more effective for tougher surfaces. Ultimately, the choice between the two methods will depend on the specific needs of the project and the desired outcome. It’s important to carefully consider the factors involved and make an informed decision to achieve the best results. Contact us to talk to one of our experts to see which option would be best for your project.

Structure Inspections

What happens during structural inspections?

Structural inspections are all about helping you understand the health of your building. The inspector will check the foundation and framework and look for damage that could be caused by structural issues. After the inspection is performed, the inspector will go over the results and the next steps on how to remedy the issues. The damages to look out for include:

- Cracked or Deteriorating Concrete – The concrete in your building should be smooth. When there are cracks, bumps, bubbles, or anything that looks out of the ordinary, it may be time to have it looked at by a professional. Concrete has natural wear and tear over time but factors such as water, ice, or corrosion of steel support could prematurely decay your building’s concrete.

- Bowing or Misshapen Foundations – If there is anything abnormal about your foundation, you will need to have it inspected. Issues in your foundation can cause problems throughout your whole building and, in extreme cases, cause structural failure.

- Cracks in Walls – This can be caused by the foundation shifting or bowing.

- Leaks – If you see wet spots or water damage in the wall, ceiling, or flooring, you’ll want to get it inspected. Whether it’s from the roof or foundation issues, the leak can cause mold and become dangerous for your building’s occupants.

When do you need a structural inspection?

If you are planning on doing work to your building that requires a building permit, the building has to be inspected and approved before the work can begin. You might also get a structural inspection if you are buying a new building or selling the one you own. If leaks or other damages are an issue, you may consider a structural inspection to rule out concrete or foundation damage. You might also want to have the structure inspected if a major storm or natural disaster took place.

Taylor Waterproofing offers structural inspections. If you have any of the issues above, are in the market to buy, or just want to check the health of your current building, give us a call today or contact us through our website here.

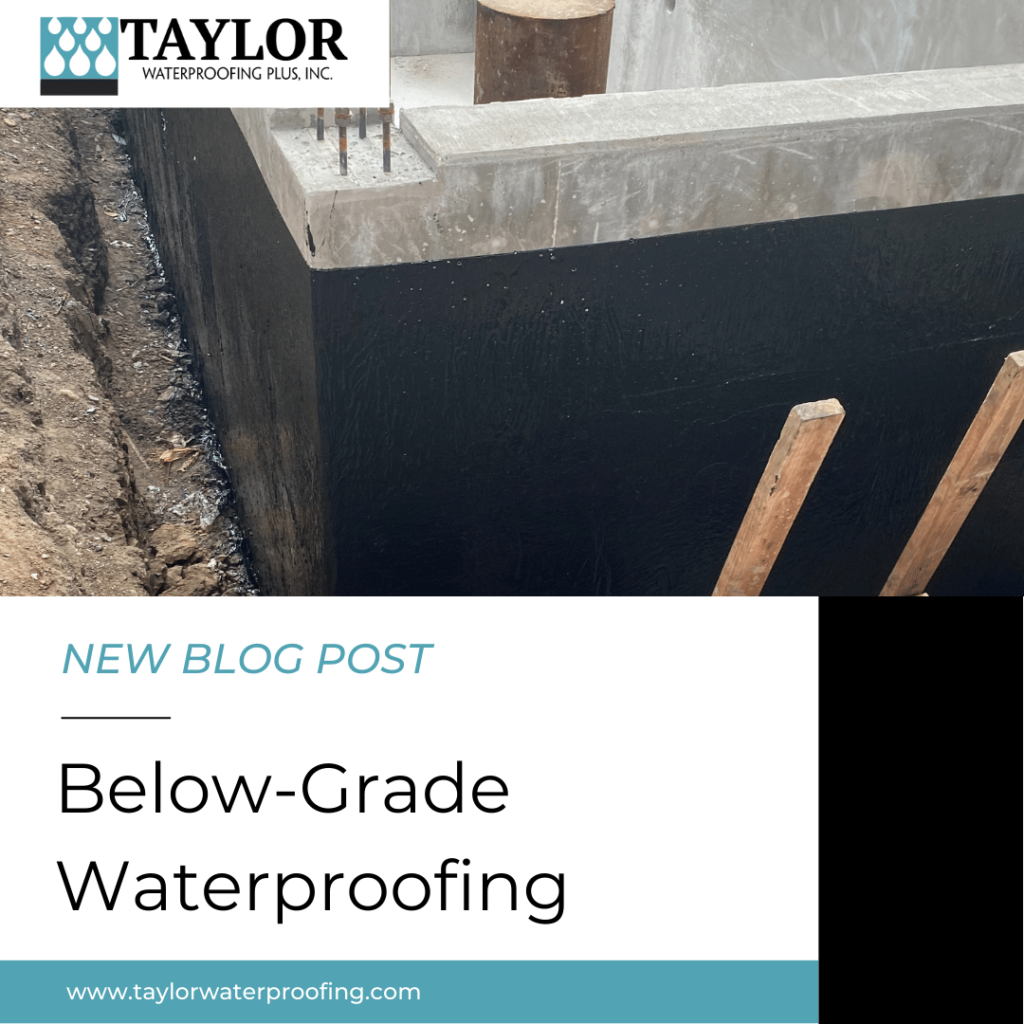

Below-Grade Waterproofing

When you are constructing a building or unground structure, such as an underground parking garage or basement, you’ll need below-grade waterproofing to make sure it keeps its structural integrity. These areas are subject to flooding and waterproofing is a way to prevent damage and increase the life of the structure. There are a few ways to install this waterproofing system, but the process refers to applying a waterproof coating or other material to the walls of the foundation, usually during the construction stages.

Because buildings’ foundations are constructed of concrete, it is porous and can crack over time. One health hazard to consider is mold and mildew growth due to water damage. Below-grade waterproofing creates a barrier between your building’s foundation and the earth. Along with below-grade waterproofing, making sure the building has proper drainage is also a huge aspect of mitigating these types of issues.

Below-Grade Waterproofing Types

Positive-Side Waterproofing – This application is done on the outside of the foundation where it will touch soil. This can consist of fluid-applied seamless membranes, sheet systems, or a combination of the two.

Negative-Side Waterproofing – This is applied to the interior of the building. It stops water and other materials from entering the building but not from penetrating the foundation. Because of this, it is usually done in conjunction with positive-side waterproofing or when the positive-side can not be done.

Overall, below-grade waterproofing protects your building by ensuring there is a barrier between the foundation and the outside elements. Without waterproofing, you could deal with structural issues, flooding, water damage, and toxic materials. When done correctly, below-grade waterproofing greatly reduces the risk of damage and protects your building and investment. To talk to one of our team members about the best waterproofing options for your project, contact us today!

Davit Testing and Why it’s Important

What is a Davit?

If you are planning on having your building’s windows washed or waterproofed, the first thing you want to consider is safety. Roof davits, also referred to as tie-back anchors or tie-downs, allow contractors or trained employees to access the facade of the building. By using a davit, you can suspend a platform down the side of the building so the individuals performing the service can have a steady and safe working platform for maintenance, cleaning, and repair services. These anchors are required for any building with 4 or more stories and 3 or more stories if ground equipment can not easily reach areas that need to be repaired or maintained.

Davit Specifications & Testing

Davit testing and inspections are an important part of your building’s safety. OSHA has several standards to regulate davits to ensure safety. Davits must be ASTM A36 steel construction and fully galvanized finish to ASTM A123 standards. After the davit is installed on your roof, it must be tested and inspected.

A davit system must be recertified every ten years. Recertification is required every five years if adhesive, epoxy, or chemically bonded anchorages are used. When testing the equipment to OSHA requirements and certification, a load test will be done to verify the strength of the davit. These anchors need to withstand an ultimate load of 5,000 lbs in any direction. While it is required that the davit be recertified every ten years, a visual inspection will need to be performed once a year.

Why is Davit Testing Important?

There are many reasons to have davit testing performed. It ensures that your building is up to code and help prevents falls. It is a vital part of ensuring a safe work environment. This also keeps you in compliance with OHSA and other government agencies regulations.

Our team can help you make sure buildings and davits are up to code and safe. Our trained professionals ensure structural integrity and compliance through testing and visual inspections. Contact us today to learn more about davit testing or schedule a service.

Epoxy Flooring and Overlays

Epoxy is a resin flooring that is low-maintenance and easy to maintain. It is great for industrial and commercial applications, such as warehouses, parking garages, and office buildings because of its durability and safety aspects. Once applied it creates a hard covering or coating over concrete that is resistant to scratches.

What Are the Benefits of Epoxy Flooring?

Aesthetic – Epoxy floors and overlays are very customizable and you can achieve the look and feel you want in the space.

Protect Against Wear and Tear – This flooring is very durable. It is resistant to chemicals that might be present in a commercial setting. It is also resistant to gasoline and oil, making it an excellent option for garages. Epoxy flooring can bear a lot of weight, also making it a great option for industrial flooring where forklifts and other large equipment are driving on it regularly. Other types of flooring can become stained or cracked.

Easy Cleaning – Cleaning epoxy floors is as easy as using soap and a mop or spraying it down with a water hose. It does not absorb water, making it easy to clean up spills. These floors don’t require waxing or stripping like other types of flooring so it makes it a low-maintenance option.

Slip-Resistant – Adding aggregate to the epoxy mix before the application will achieve the level of slip resistance needed for your certain situation. This can help decrease the number of accidents and increase workplace safety. It also makes it a great option for parking garages because of the high foot and vehicle traffic.

Sterile Environment – Traditional flooring, such as tile, can harbor mildew, mold, and bacteria in the seams and grout. Flooring with seams can also be hard to clean when there are spills. It can be difficult to remove the contaminants without harsh chemicals. Making sure the floors are clean can protect the occupants of the building, especially if your business is in the food or healthcare industry. Epoxy flooring creates a waterproof seal over the concrete so mold and other harmful substances can’t live or grow.

Epoxy flooring is an overall good and versatile option. Many businesses and industries can benefit from the many features it provides. If you would like to talk to one of our team members about installing epoxy flooring for your commercial application, contact us today.

What Causes Corrosion on Your Building & How to Stop it

What is Corrosion and What are its Effects?

Corrosion is a chemical process that slowly breaks down the materials of buildings. Not only does this damage the aesthetics and value of your building or structure, but it can cause construction failure if not addressed in a timely manner. Corrosion weakens these buildings and materials can start to chip, crack and break off.

Rust

Rust is the most common form of corrosion when it comes to buildings. It occurs when water comes into contact with metals and is exposed to oxygen. It can appear on a steel building and in reinforced concrete. Rust stains can also appear on the brick and the surface of concrete.

What to Look For

Sometimes, corrosion is very obvious and can be seen from the outside. Looking for rust and rust stains will be a good indicator of where the damage is coming from. Other times, the damage is hidden. There could be a leak if water spots or damage are present on the ceiling or walls. Because rust is caused by water on metal, a leak can cause corrosion on the framing of the building that is not easily visible.

How we can help:

Sandblasting or Waterblasting: Rust can leave stains on the outside of your building from water running down the side. Sandblasting or waterblasting will remove the rust and rust stains. It will also remove grime, such as mold and dirt.

Sealant Removal and Replacement: By waterproofing your building, you are cutting down on the chance of corrosion. To learn what sealant and options are best for your business, contact us today to talk to one of our team members.

Structural Concrete Repair: Corrosion can damage structural concrete. Our team can inspect the concrete and help decide the best way to repair it.

Structure Inspections: Corrosion can affect the structural integrity of your building. If you have had or having issues with corrosion or rust, you want to make sure your building is safe. We can inspect the building and tell you what actions need to be taken.

Over time, rust and other corrosion can happen to your building, especially if there is a leak. As your building ages, preventative measures will need to be taken to make sure your building is safe. Contact us today to learn more about our services and how we can help you.

Waterproofing

Waterproofing your building is one of the most important things you can do to preserve it. Our team at Taylor Waterproofing can inspect your commercial or historical building and help you decide what options and services are best for your property. Without waterproofing measures in place, your building could be at risk.

Risks of Not Waterproofing

- Foundation Can Become Weak – When standing water is surrounding your foundation, it impacts the integrity of the concrete. It can also cause water to get into your HVAC system.

- Bacteria, Mold, and Pests – When leaks happen, wet drywall and other building material are a breeding ground for unwanted bacteria and mold and can also lead to insects finding their way into your building. All of these are health hazards for those who work in your building.

- Water Damage – Along with growing mold, water damage can cause drywall and ceiling materials to become weakened and potentially break.

- Injury or Damage to Property – If something is damaged due to leaks, injury or damage to occupants’ property could occur. Depending on the circumstance, you could be held liable for this injury or damage.

How We Can Help

Since 1995, our team has been dedicated to helping you protect your property and investment by waterproofing and preventing damage. We offer many services to waterproof your building.

Below-Grade Waterproofing

Because concrete is a porous material, it can crack over time, especially if there is water-creating pressure on it. Below-grade waterproofing creates a barrier between the foundation’s concrete and the water or earth. This process is usually done while the building is being constructed, but there are options for already constructed properties.

Deck Coating

If you have a wooden deck on your property, a deck coating may be right for you. Repeated moisture over time can cause it to rot. It can also help prevent injury because the surface will not be as slippery.

Wet Glazing

For waterproofing windows, wet glazing is the best option. This process uses pourable grout to seal the edges where the window and building meet.

Most of the time when we are asked to perform waterproofing services, there is already a leak. While we can help remedy this situation, the time to waterproof your building is before there is an issue. Once a leak is seen or noticed, it could have already done hundreds, if not thousands, dollars worth of damage. To talk to one of our team members about waterproofing options, contact us today!

Importance of Building Preservation

Building preservation might look different from building to building depending on the type. At Taylor Waterproofing, we offer a wide range of services so your building can stay in the best shape possible. Many different factors could cause corrosion to your building over time. With our wide range of services, we can make sure that your building is protected.

Building Preservation Services:

- Waterblasting

Not only does water blasting your building make it look nicer, but it also helps reduce the cost and need for repairs. When a building goes without washing, mildew, dirt, and mold can build up, speeding up damage and the need for repairs.

- Structure inspections

Problems with the structure of a building can lead to water damage, sagging roofs, and uneven surfaces and could cause safety issues. After an inspection, our team can help you know exactly what your building needs in terms of structure.

- Structural concrete repair

Our trained professionals can identify where your concrete is damaged and what’s the best way to go about repairing the structure. Damaged structural concrete can not only be a safety concern but also hinder the functionality of your building.

- Wet glazing

This is one way we help waterproof your building. Wet glazing is the process of applying a liquid silicon sealant between the window glass and the frame to seal it. The seal it creates is strong and resilient to weathering.

These are just a few of the services that we offer. To view our full service list, click this link.

To get in touch with us to see how we can help with your building preservation project, check out our contact us page here.